Recovery of Indium Metal from Waste ITO Targets

Shaoguan Yuntian Metals

ITO (indium tin oxide) films are the most commonly used transparent conductive materials. They are typically deposited onto glass substrates by magnetron sputtering; however, the utilization rate of the ITO targets is relatively low—only about 30% is effectively used, while the remaining 70% becomes waste targets or scrap.

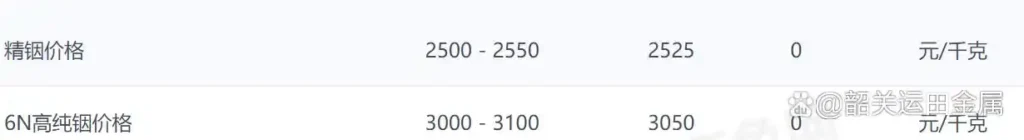

Current Indium Price:

With the rapid growth of the display and new energy industries, the demand for indium continues to increase. Given the limited mineral resources, the price of indium has remained high over the long term.

The “Hidden Urban Mine” in Waste ITO Targets

ITO targets are sintered from indium oxide and tin oxide. Global statistics show that less than one-third of the indium from the targets is actually deposited onto the films; the rest ends up as waste material. If properly recycled, this waste represents a valuable “urban mine.”

In a large LCD manufacturing enterprise, several tons of waste targets are generated annually. Considering the current price of indium, the potential value of this waste is considerable.

Exploration of Recovery Processes

Separating indium from tin in waste ITO targets is challenging due to their close association. Researchers have tested several methods:

- Chemical dissolution: Waste is dissolved in acid, followed by precipitation separation. However, tin tends to form gelatinous compounds, complicating separation and limiting scalability.

- Alkali fusion: Using alkali and high temperature to separate indium and tin, with limited efficiency and partial tin removal only.

- Reduction plus electrolysis: Currently the most effective approach. Waste is first reduced to an indium-tin alloy, then leveraging the electrochemical differences between indium and tin, two electrolysis steps are performed to extract high-purity indium.

Experimental Results

Studies show that hydrogen reduction yields an alloy containing over 90% indium, with a direct recovery rate around 97%. Carbon reduction, though conducted at higher temperature, offers a simpler process and achieves similar recovery rates.

During subsequent electrolysis:

- The first electrolysis effectively removes most impurities.

- The second electrolysis produces metallic indium with purity up to 99.993%, fully meeting industrial standards.

Overall, this process achieves a stable recovery rate exceeding 95%, combining high efficiency with reliability.

Economic and Environmental Benefits

Economically, with indium priced around 1600 RMB/kg, recovering even tens of kilograms from waste targets can generate significant revenue. Environmentally, recycling reduces reliance on primary indium ores, mitigates ecological damage from mining, and lowers industrial solid waste discharge. Industrially, this process substantially decreases ITO target consumption costs, providing new resource security for the display, photovoltaic, and related sectors.

Shaoguan Yuntian Metals Summary: Waste ITO targets constitute a hidden “indium mine.” Through reduction and electrolysis, indium can be efficiently recovered with purity approaching “4N” quality, producing high-grade metal suitable for industrial use.