Achieving Economies of Scale and Reducing Unit Costs in Gallium Recovery Processes

Abstract

Economies of scale in gallium (Ga) recovery can be realized through centralized raw material processing, integrated process optimization, and synergistic extraction of by-products. Large-scale recovery plants (annual throughput ≥500 tons of Ga-containing waste) can reduce unit costs to below $35/kg, representing a 56% decrease compared to smaller facilities (> $80/kg). Key measures include: (1) blending multiple waste sources (semiconductor waste, LED residues, photovoltaic scraps) to increase equipment utilization to 85%; (2) employing combined chlorination-electrolysis processes to shorten production flows and reduce energy consumption to 8 kWh/kg; (3) extracting co-metals such as aluminum and indium to generate additional revenue covering 30% of total costs. Further cost compression is achievable through intelligent sorting systems and development of regional recycling networks to reduce logistics and sorting expenses.

- Relationship Between Gallium Recovery Costs and Economies of Scale

1.1 Cost Structure Analysis (Example: Gallium Arsenide Waste)

- Raw material pretreatment: 28% (crushing, sorting, acid/base cleaning)

- Metallurgical purification: 45% (leaching, extraction, electrolysis)

- Environmental treatment: 17% (solidification of waste residues, wastewater purification)

- Management and logistics: 10%

1.2 Scale Economy Threshold Estimation

- Break-even analysis: For annual throughput below 100 tons, fixed costs (equipment depreciation, environmental assessments, etc.) exceed 50% of total costs, resulting in unit costs above $100/kg;

- At 500 tons per year, variable costs dominate (70%), reducing unit costs to $35/kg.

- Learning curve effect: Unit cost decreases by 12% with every doubling of cumulative processed volume due to improved operational proficiency.

- Optimization of Large-Scale Recovery Technology Pathways

2.1 Synergistic Treatment of Multi-Source Waste

- Blending strategy: Mixed processing of LED chips (15% GaN), photovoltaic cutting waste (8% Ga), and semiconductor wafers (25% GaAs) enables synchronous metal dissolution within a unified hydrochloric acid leaching system (6 mol/L HCl).

- Equipment sharing benefits: Facilities at the 1,000-ton scale can share leaching tanks, centrifuges, and other equipment, reducing investment intensity by 40% compared to decentralized setups.

2.2 Innovative Short-Process Metallurgy

- Chlorination volatilization process: Waste reacts with Cl₂ at 600°C to form GaCl₃ with >95% conversion; condensed GaCl₃ is directly electrolyzed to yield 99.99% crude gallium, eliminating three steps compared to traditional alkaline leaching and electrolysis routes.

- Selective electrolysis: Pulsed current electrolysis (100 Hz frequency) increases gallium deposition current efficiency from 65% to 88%, lowering direct current energy consumption from 12 kWh/kg to 8 kWh/kg.

2.3 By-product Value-Added Recovery

- Aluminum-gallium co-extraction: pH adjustment to 4 preferentially precipitates Al(OH)₃ with purity above 98%, generating an additional $150 revenue per ton of waste.

- Trace metal enrichment: Ion exchange columns recover indium and germanium from raffinate, contributing supplementary revenue of $200/kg.

- Cost Reduction Strategies via Intelligent and Centralized Approaches

3.1 Intelligent Sorting Systems

- X-ray fluorescence (XRF) sorting: Online detection of gallium content in waste with ±0.2% accuracy and sorting speed of 2 tons/hour; feedstock grade variability narrows from ±15% to ±5%.

- Digital twin optimization: COMSOL multiphysics simulations expand leaching tank volume to 20 m³, tripling batch processing capacity.

3.2 Regional Recycling Network Development

- Centralized processing hubs: Establish 10 satellite collection points within a 300 km radius, reducing logistics costs from $0.8/kg·km to $0.3/kg·km.

- Standardized pretreatment: Satellite stations perform uniform crushing and magnetic separation (removing iron), decreasing transport weight by 40%.

- Policy Drivers and Business Model Innovations

4.1 Circular Economy Legislation and Incentives

- Extended Producer Responsibility (EPR): The EU mandates electronics firms to bear gallium recycling costs (e.g., Germany’s €0.2/gram recycling subsidy), ensuring stable feedstock supply for large-scale plants.

- Tax incentives: China offers a 70% VAT rebate on recycled gallium enterprises, easing capital pressure.

4.2 Vertical Integration of the Industry Chain

- Closed-loop from waste to metal to product: A group integrating LED manufacturing and recycling achieves an internal gallium recycling rate over 60%, reducing comprehensive costs by 25%.

- Long-term supply agreements: Five-year contracts with downstream semiconductor manufacturers (e.g., annual supply of 50 tons) stabilize capacity utilization above 80%.

- Representative Case Studies

5.1 Major Group Example

- “Super-factory” model: €120 million investment in an 800-ton annual waste processing plant integrating microwave-assisted leaching (70% reduction in reaction time) and membrane electrolysis (99.2% gallium recovery), achieving unit costs of $31/kg.

- By-product revenues: Annual recovery of 1,200 tons aluminum and 8 tons indium contributes 35% of total revenue.

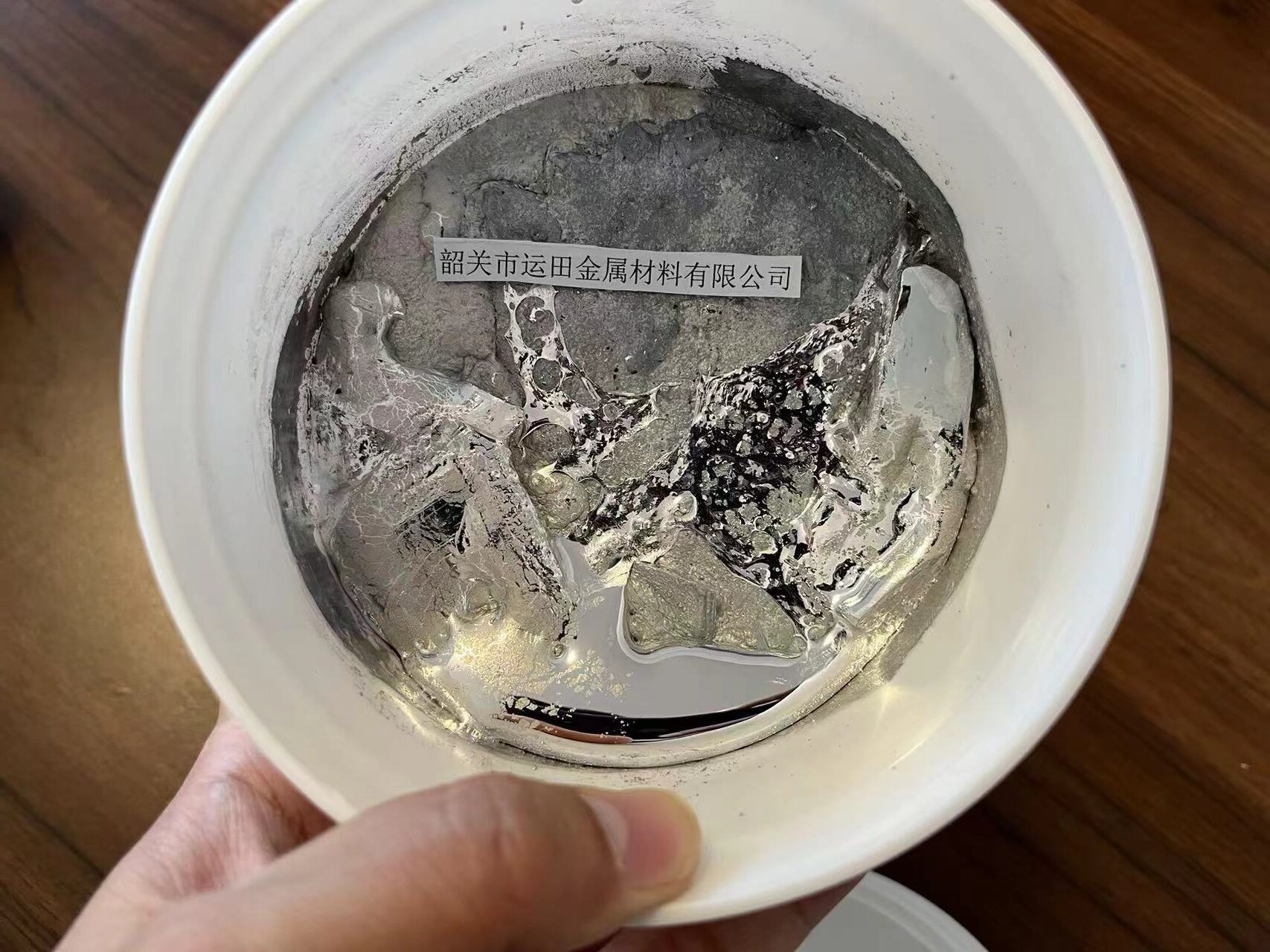

5.2 Company Example

- Urban mining development: Five electronic waste collection centers in the Yangtze River Delta region apply chlorination-electrolysis processes producing 25 tons of recycled gallium annually at costs 22% below industry average.

- Intelligent logistics: Blockchain traceability technology increases procurement efficiency by 40%, reducing inventory turnover from 45 to 25 days.

- Prospects for Technological and Economic Advancement

6.1 Cost Reduction Pathways

- 2025 target: Unit cost ≤ $25/kg through widespread adoption of plasma chlorination technology and increasing renewable electricity share to 50%.

- 2030 forecast: Fully automated plants with AI process control approach costs near $15/kg, close to primary gallium mining costs.

6.2 Market Scale Linkage Effects

- Demand drivers: 5G base station GaN devices and new energy vehicle power modules propel gallium demand CAGR to 12%, expanding the recycling market to $4.5 billion by 2028.

- Price equilibrium mechanism: Recycled gallium prices stabilize at 70–80% of primary gallium, encouraging downstream preference for circular materials.

Conclusion

Achieving economies of scale in gallium recovery depends on centralized raw material processing, innovative short-process technologies, and intelligent management. Establishing recycling plants with annual capacities above 500 tons and developing integrated chlorination-electrolysis processes can reduce unit costs below $35/kg. Policy support and vertical industry integration will further enhance cost competitiveness. By 2030, recycled gallium costs are expected to decline by 57% compared to 2023, facilitating the full commercialization of gallium resource recycling systems.

Achieving Economies of Scale and Reducing Unit Costs in Gallium Recovery Processes

Abstract

Economies of scale in gallium (Ga) recovery can be realized through centralized raw material processing, integrated process optimization, and synergistic extraction of by-products. Large-scale recovery plants (annual throughput ≥500 tons of Ga-containing waste) can reduce unit costs to below $35/kg, representing a 56% decrease compared to smaller facilities (> $80/kg). Key measures include: (1) blending multiple waste sources (semiconductor waste, LED residues, photovoltaic scraps) to increase equipment utilization to 85%; (2) employing combined chlorination-electrolysis processes to shorten production flows and reduce energy consumption to 8 kWh/kg; (3) extracting co-metals such as aluminum and indium to generate additional revenue covering 30% of total costs. Further cost compression is achievable through intelligent sorting systems and development of regional recycling networks to reduce logistics and sorting expenses.

- Relationship Between Gallium Recovery Costs and Economies of Scale

1.1 Cost Structure Analysis (Example: Gallium Arsenide Waste)

- Raw material pretreatment: 28% (crushing, sorting, acid/base cleaning)

- Metallurgical purification: 45% (leaching, extraction, electrolysis)

- Environmental treatment: 17% (solidification of waste residues, wastewater purification)

- Management and logistics: 10%

1.2 Scale Economy Threshold Estimation

- Break-even analysis: For annual throughput below 100 tons, fixed costs (equipment depreciation, environmental assessments, etc.) exceed 50% of total costs, resulting in unit costs above $100/kg;

- At 500 tons per year, variable costs dominate (70%), reducing unit costs to $35/kg.

- Learning curve effect: Unit cost decreases by 12% with every doubling of cumulative processed volume due to improved operational proficiency.

- Optimization of Large-Scale Recovery Technology Pathways

2.1 Synergistic Treatment of Multi-Source Waste

- Blending strategy: Mixed processing of LED chips (15% GaN), photovoltaic cutting waste (8% Ga), and semiconductor wafers (25% GaAs) enables synchronous metal dissolution within a unified hydrochloric acid leaching system (6 mol/L HCl).

- Equipment sharing benefits: Facilities at the 1,000-ton scale can share leaching tanks, centrifuges, and other equipment, reducing investment intensity by 40% compared to decentralized setups.

2.2 Innovative Short-Process Metallurgy

- Chlorination volatilization process: Waste reacts with Cl₂ at 600°C to form GaCl₃ with >95% conversion; condensed GaCl₃ is directly electrolyzed to yield 99.99% crude gallium, eliminating three steps compared to traditional alkaline leaching and electrolysis routes.

- Selective electrolysis: Pulsed current electrolysis (100 Hz frequency) increases gallium deposition current efficiency from 65% to 88%, lowering direct current energy consumption from 12 kWh/kg to 8 kWh/kg.

2.3 By-product Value-Added Recovery

- Aluminum-gallium co-extraction: pH adjustment to 4 preferentially precipitates Al(OH)₃ with purity above 98%, generating an additional $150 revenue per ton of waste.

- Trace metal enrichment: Ion exchange columns recover indium and germanium from raffinate, contributing supplementary revenue of $200/kg.

- Cost Reduction Strategies via Intelligent and Centralized Approaches

3.1 Intelligent Sorting Systems

- X-ray fluorescence (XRF) sorting: Online detection of gallium content in waste with ±0.2% accuracy and sorting speed of 2 tons/hour; feedstock grade variability narrows from ±15% to ±5%.

- Digital twin optimization: COMSOL multiphysics simulations expand leaching tank volume to 20 m³, tripling batch processing capacity.

3.2 Regional Recycling Network Development

- Centralized processing hubs: Establish 10 satellite collection points within a 300 km radius, reducing logistics costs from $0.8/kg·km to $0.3/kg·km.

- Standardized pretreatment: Satellite stations perform uniform crushing and magnetic separation (removing iron), decreasing transport weight by 40%.

- Policy Drivers and Business Model Innovations

4.1 Circular Economy Legislation and Incentives

- Extended Producer Responsibility (EPR): The EU mandates electronics firms to bear gallium recycling costs (e.g., Germany’s €0.2/gram recycling subsidy), ensuring stable feedstock supply for large-scale plants.

- Tax incentives: China offers a 70% VAT rebate on recycled gallium enterprises, easing capital pressure.

4.2 Vertical Integration of the Industry Chain

- Closed-loop from waste to metal to product: A group integrating LED manufacturing and recycling achieves an internal gallium recycling rate over 60%, reducing comprehensive costs by 25%.

- Long-term supply agreements: Five-year contracts with downstream semiconductor manufacturers (e.g., annual supply of 50 tons) stabilize capacity utilization above 80%.

- Representative Case Studies

5.1 Major Group Example

- “Super-factory” model: €120 million investment in an 800-ton annual waste processing plant integrating microwave-assisted leaching (70% reduction in reaction time) and membrane electrolysis (99.2% gallium recovery), achieving unit costs of $31/kg.

- By-product revenues: Annual recovery of 1,200 tons aluminum and 8 tons indium contributes 35% of total revenue.

5.2 Company Example

- Urban mining development: Five electronic waste collection centers in the Yangtze River Delta region apply chlorination-electrolysis processes producing 25 tons of recycled gallium annually at costs 22% below industry average.

- Intelligent logistics: Blockchain traceability technology increases procurement efficiency by 40%, reducing inventory turnover from 45 to 25 days.

- Prospects for Technological and Economic Advancement

6.1 Cost Reduction Pathways

- 2025 target: Unit cost ≤ $25/kg through widespread adoption of plasma chlorination technology and increasing renewable electricity share to 50%.

- 2030 forecast: Fully automated plants with AI process control approach costs near $15/kg, close to primary gallium mining costs.

6.2 Market Scale Linkage Effects

- Demand drivers: 5G base station GaN devices and new energy vehicle power modules propel gallium demand CAGR to 12%, expanding the recycling market to $4.5 billion by 2028.

- Price equilibrium mechanism: Recycled gallium prices stabilize at 70–80% of primary gallium, encouraging downstream preference for circular materials.

Conclusion

Achieving economies of scale in gallium recovery depends on centralized raw material processing, innovative short-process technologies, and intelligent management. Establishing recycling plants with annual capacities above 500 tons and developing integrated chlorination-electrolysis processes can reduce unit costs below $35/kg. Policy support and vertical industry integration will further enhance cost competitiveness. By 2030, recycled gallium costs are expected to decline by 57% compared to 2023, facilitating the full commercialization of gallium resource recycling systems.